VISIDISK

The Hazard:

Any hazardous material being stored must have more than one barrier between a hazardous material and the outside environment or workplace. A single leaking or accidentally opened valve should not result in a dangerous and uncontrolled release of hazardous material. Process plants are busy places, but even with safe work procedures in place, when you add human factor the secondary barrier, the cap, may possibly be forgotten to be fitted.

The Solution:

The Visidisk will give you a quick visual indication that the secondary barrier (the cap) is in place. This makes it very easy to check and when auditing the process plant you can see it is in a safe operational state.

How It Works:

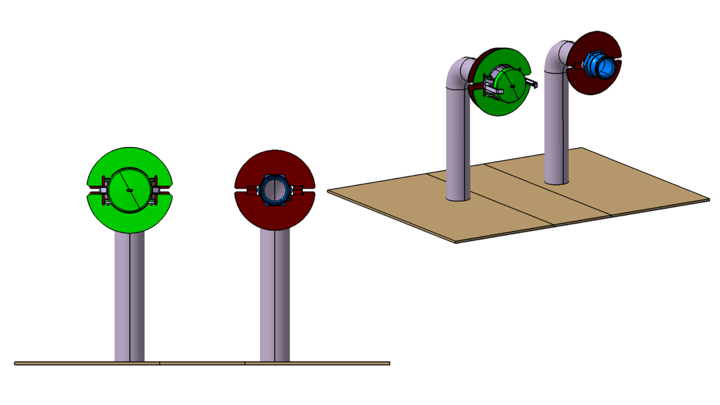

If you see a RED Visidisk your process plant is NOT safe or compliant

If you see GREEN you ARE safe and compliant

As part of continuous improvement and using visual techniques, the Visidisk can be retrofitted to existing process plants or included in the design of new systems. The Visdisk system is currently available in sizes from 1” to 4” and in a material that will withstand harsh environments.